Download Spec Sheet402.95 KB

Download 3D PDF566.59 KB

Download STP27.56 KB

Description

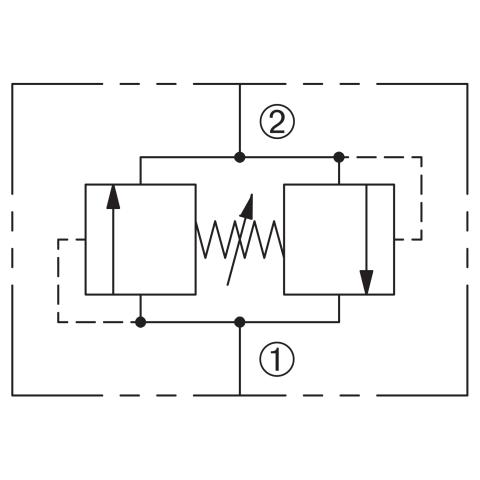

An adjustable, bi-directional poppet type cartridge valve designed to limit pressure in hydraulic circuits.

Operation

The DBRVS-100 is comprised of two relief valves which prevent flow from ➀ to ➁ or ➁ to ➀ until the set crack pressure is achieved at either port ➀ or ➁. When the set crack pressure is reached, the poppet unseats allowing flow from ➀ to ➁ or ➁ to ➀ protecting the circuit from over pressurization.

Features and Benefits

- Rapid response to pressure surges.

- Low pressure rise.

- Hardened poppet and seat for long life.

- Hidden adjustment (tamper resistant).

- Industry common cavity.

Specifications

Max Operating Pressure (psi)

5000

Flow gpm

20.0

Flow lpm

75.7

Cavity

Valve Style

Poppet

- Operating Pressure: 5000 PSI (345 Bar)

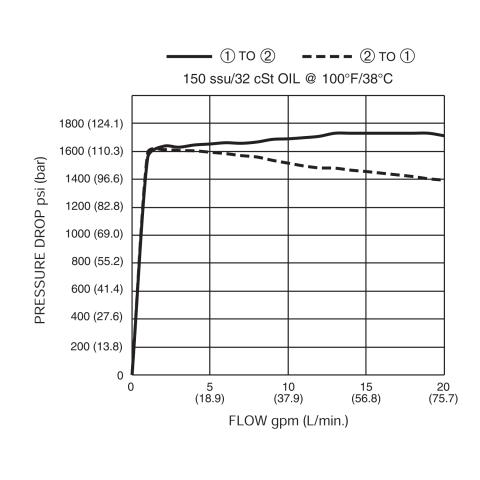

- Flow:

- See PRESSURE DROP VS. FLOW graph.

- Nominal Flow 20 GPM (75.7 L/min).

- Internal Leakage: 5 in.3/min. (82cc/min.) max. at reseat.

- Crack Pressure Defined: Determined at .25 gpm (0.9 L/min.)

- Reseat Pressure: Nominal 80% of crack pressure.

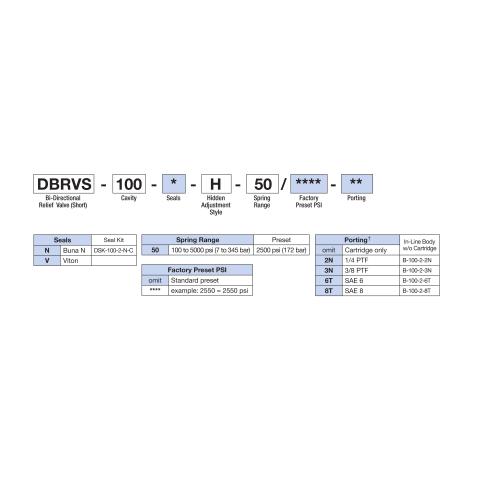

- Spring Range: 100 to 5000 PSI (7 to 345 Bar).

- Preset: See HOW TO ORDER

- Temperature: -30° F to +250° F (-35°C to +120° C)

- Recommended Filtration: ISO 20/18/14

- Fluids: Mineral-based fluids. For other fluid compatibility consult factory.

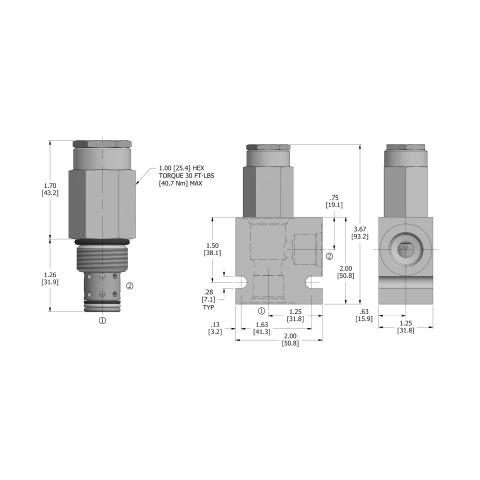

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 PSI (207 Bar).