Download Spec Sheet1.01 MB

Download 3D PDF1.51 MB

Download STP31.22 KB

Description

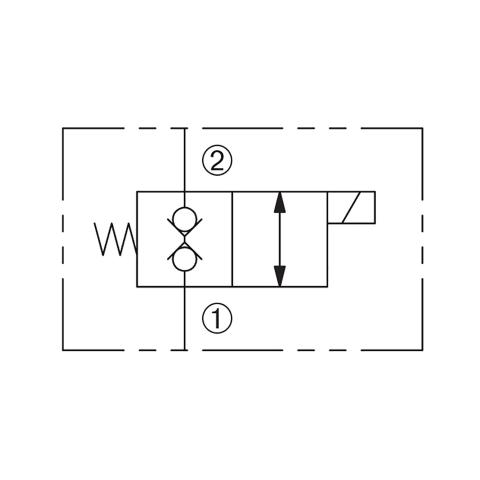

A cartridge valve designed with positive shut off, blocking in both directions, to be used in load holding applications.

Operation

When de-energized, the DSV-080-2NCSP blocks flow in both directions. When energized, the poppet shifts to allow flow in either direction.

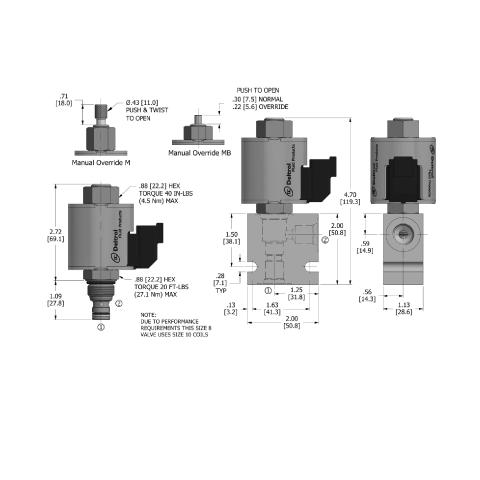

Operation of Manual Override Option: To override, push button in to activate. To return to normal valve function, release button.

Features and Benefits

- Continuous-duty solenoid.

- Uses Size 10 coils.

- Hardened poppet and seat for long life and low leakage.

- Efficient wet-armature construction.

- Cartridges are voltage interchangeable.

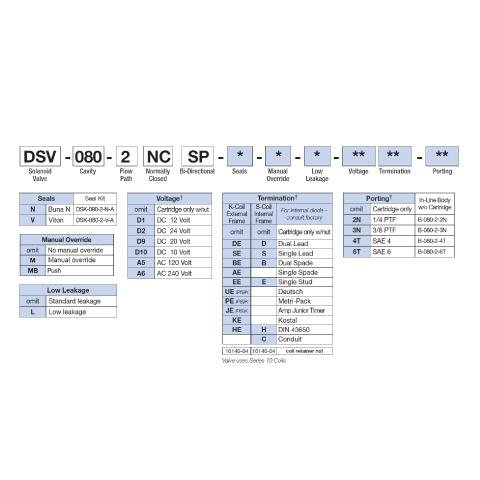

- Optional coil voltages and terminations.

- Low leak valve available.

- Manual override option.

- Industry common cavity.

Specifications

Max Operating Pressure (psi)

3000

Flow gpm

5.0

Flow lpm

18.9

Cavity

Valve Style

Poppet

- Operating Pressure: 3000 PSI (207 Bar)

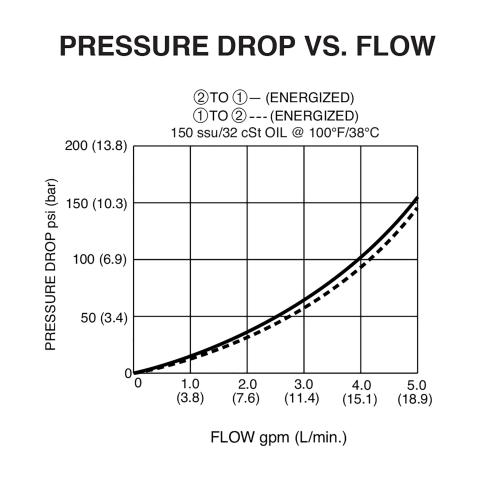

- Flow: See PRESSURE DROP VS. FLOW graph.

- Internal Leakage:

- 5 drops/min. max. at 3000 PSI (207 Bar)

- Low leak available - Less than 2 drops/min. max. at 3000 PSI (207 Bar)

- Temperature: -30°F to +250°F (-35°C to +120°C)

- Coil Duty Rating: Continuous from 85% to 110% of rated voltage.

- Current Draw: 12 VDC is 1.8 amps.

- Minimum Pull-In Voltage: 85% of rated voltage at 3000 PSI (207 Bar)

- Response Time: 80% of final change of state with 100% voltage supplied at 100% of nominal flow rating.

- Pull-In: 12 VDC 41 m. sec.

- Drop-Out: 12 VDC 30 m. sec.

- Recommended Filtration:

- Critical Application – ISO 17/15/13

- Non-Critical Application – ISO 20/18/14

- Fluids: Mineral-based fluids. For other fluid compatibility, consult factory.

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 PSI (207 Bar).