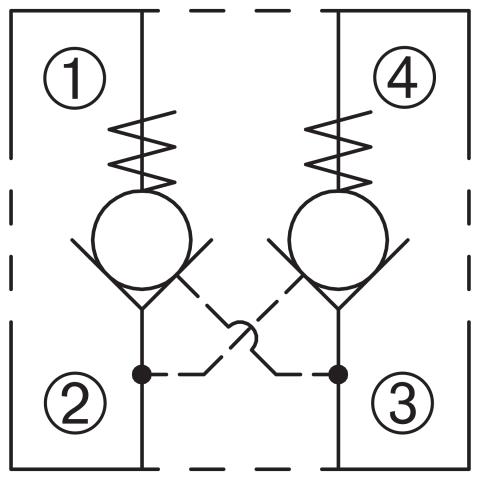

A cartridge valve designed to allow free flow in one direction while preventing flow in the opposite direction. Reverse flow can be achieved by reaching the required pilot pressure. This valve is commonly used as a load-holding or blocking valve.

Pressure at ➁ or ➂ overcomes the spring-bias poppet and allows free flow to ➀ or ➃ respectively. Flow in the opposite direction, from ➀ to ➁ or ➃ to ➂, is blocked by the poppet. When the required pilot pressure is achieved at ➁, the poppet unseats and allows flow between ➃ and ➂. When the required pilot pressure is achieved at ➂, the poppet unseats and allows flow between ➀ and ➁. The pilot piston area to poppet seat area ratio is 3:1.

- Hardened poppet and seat for long life.

- Industry common cavity.

- Operating Pressure: 3000 PSI (207 Bar)

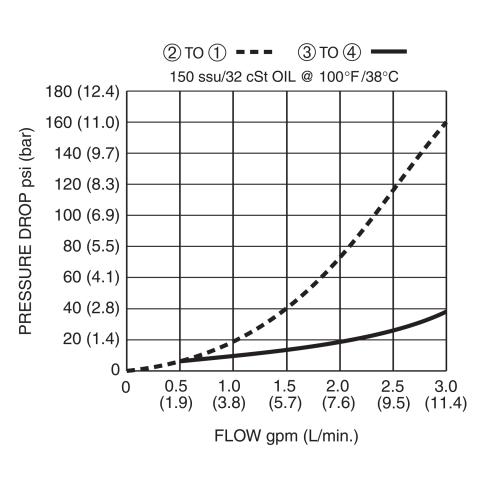

- Flow:

- See PRESSURE DROP VS. FLOW graph.

- Nominal flow 2 gpm (7.6 L/min.)

- Internal Leakage: 5 drops/min. max. at 3000 PSI (207 Bar)

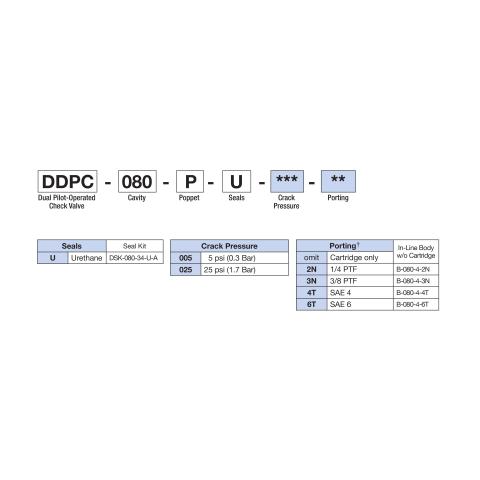

- Crack Pressure:

- 5 PSI (0.3 Bar)

- 25 PSI (1.7 Bar)

- Pilot Ratio: 3:1

- Temperature: -30°F to +250°F (-35°C to +120°C)

- Recommended Filtration:

- Critical Application – ISO 17/15/13

- Non-Critical Application – ISO 20/18/14

- Fluids: Mineral-based fluids. For other fluid compatibility, consult factory.

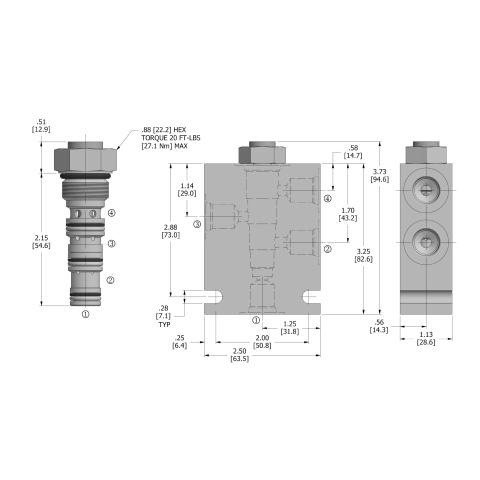

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 PSI (207 Bar).