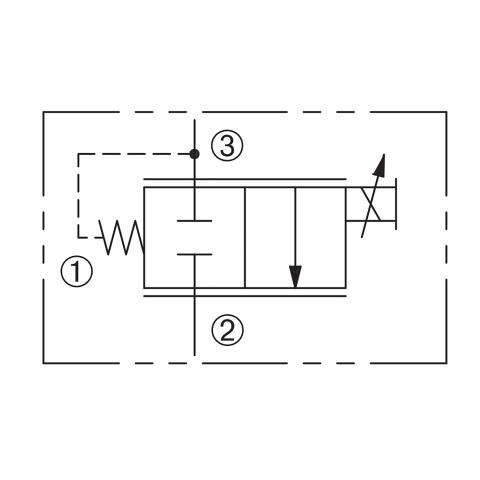

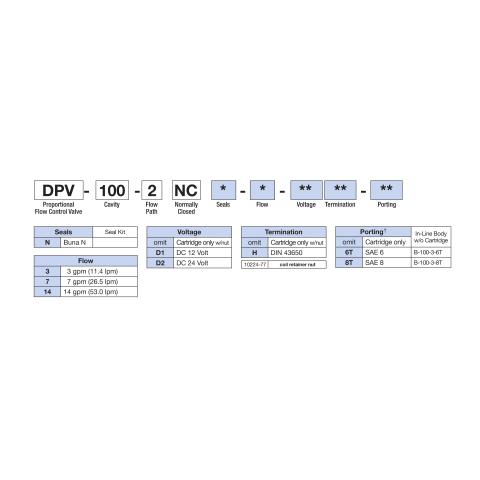

A cartridge valve designed as a normally closed, spool-type, proportional valve for use with a compensating element to provide an electrically variable pressure-compensated flow control.

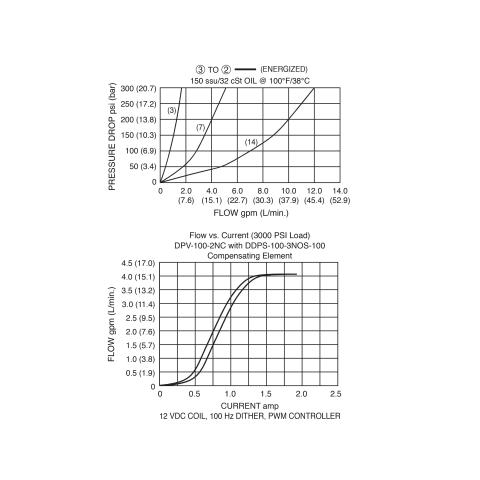

As electrical current is applied to the coil, the spool will gradually shift from closed to open as current increases to 2 amps maximum. Flow will pass from port ➂ to port ➁ up to 300 psi differential.

Port ➀ is plugged.

The valve can also function as a differential control for load sense applications.

The valve functions with industry-common controllers which provide PWM current input to 2 amps @ 12 VDC.

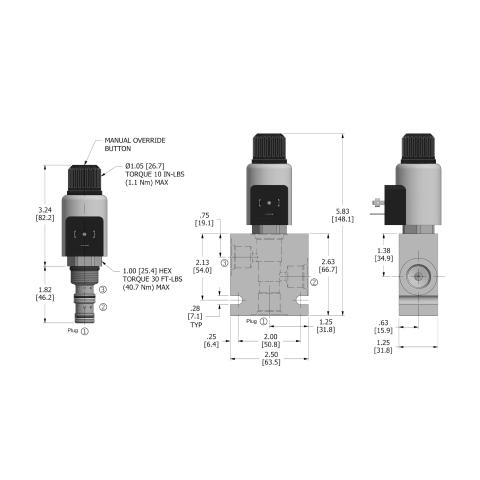

OPERATION OF MANUAL OVERRIDE:

To override, push button in to activate. To return to normal function, release button.

- Valve controllers along with portable controller programming devices to vary PWM Duty Cycle, Ramp Time, Current Limit, Dither Frequency and Amplitude, can be provided by consulting the factory.

- Hardened precision spool and sleeve for long life.

- Efficient wet-armature construction.

- Cartridges are voltage interchangeable.

- Optional coil voltages and terminations.

- Industry common cavity

- Coil: 12 volt system; Resistance 4.0 ohms @ 20˚C; Threshold Current 300 ± 70mA;

- Max. Control Current 1500 ± 200mA

- 24 volt system; Resistance 16.0 ohms @ 20˚C; Threshold Current 150 ± 35mA;

- Max. Control Current 750 ± 100mA

- Operating Pressure: 3000 psi (207 bar)

- Flow: See PRESSURE DROP VS. FLOW CURVE.

- Internal Leakage: (Per land) 10 cu in3/min (164 cc/min) max. at 3000 psi (207 bar)

- Temperature: -30°F to +250°F (-35°C to +120°C)

- Coil Duty Rating: Continuous from 85% to 110% of rated voltage.

- Recommended Filtration: ISO 16/12

- Fluids: Mineral-based fluids.

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 psi (207 bar)