A cartridge valve designed with positive shut off to be used in load holding applications.

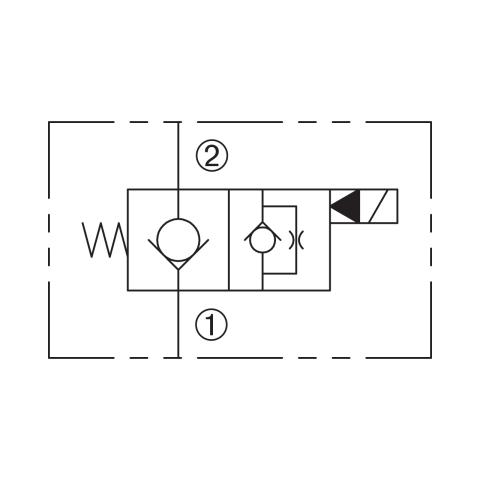

When de-energized, the DSV-080-2NCP acts as a check valve, allowing flow from ➀ to ➁, while blocking flow from ➁ to ➀. When energized, the poppet lifts to open the ➁ to ➀ flow path.

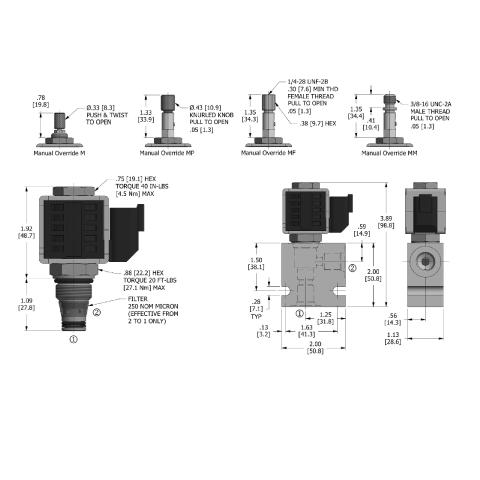

Operation of Manual Override Option M: To override, push button in, twist counterclockwise and release. In this position, the valve will remain open. To return to normal operation, push button in, twist clockwise and release. Override will be detented in this position. Option MP, MF, MM: To override, pull spring-loaded knob/adapter on top of valve. Release to return to normal operation.

- 4000 PSI (276 Bar) rating.

- Continuous-duty solenoid.

- Hardened poppet and plunger for long life and low leakage.

- Efficient wet-armature construction.

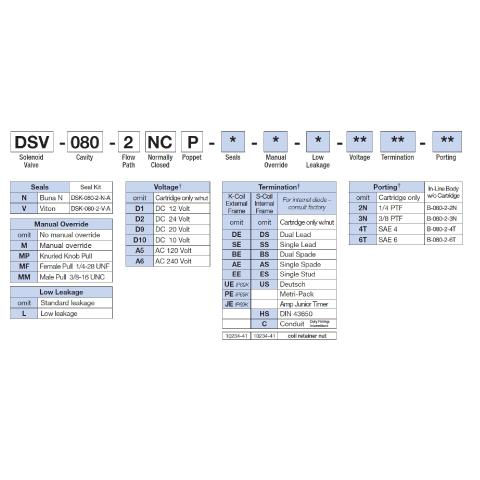

- Cartridges are voltage interchangeable.

- Optional coil voltages and terminations.

- Filter screen standard.

- Low leak option available.

- Manual override option.

- Industry common cavity.

- Operating Pressure: 4000 PSI (276 Bar)

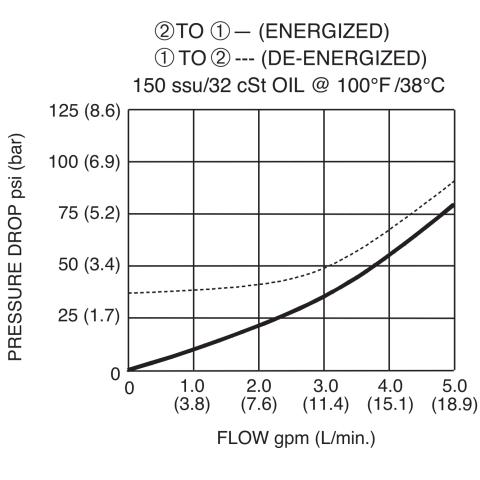

- Flow: See PRESSURE DROP VS. FLOW graph

- Internal Leakage:

- 5 drops/min. max. at 3000 PSI (207 Bar)

- Low leakage available- Less than 2 drops/min. max. at 3000 PSI (207 Bar)

- Temperature: -30° F to +250° F (-35°C to +120° C)

- Coil Duty Rating: Continuous from 85% to 110% of rated voltage.

- Current Draw: 12 VDC is 1.3 amps.

- Minimum Pull-In Voltage: 85% of rated voltage at 4000 PSI (276 Bar)

- Response Time: 80% of final change of state with 100% voltage supplied at 100% of nominal flow rating.

- Pull-In: 12 VDC 16 m. sec. Drop-Out: 12 VDC 18 m. sec.

- Recommended Filtration:

- Critical Application-ISO 17/15/13

- Non-Critical Application-ISO 20/18/14

- Fluids: Mineral-based fluids. For other fluid compatibility consult factory.

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 PSI (207 Bar).