Female-to-Female

Download Spec Sheet193.53 KB

Download 3D PDF191.29 KB

Download STP114 KB

Description

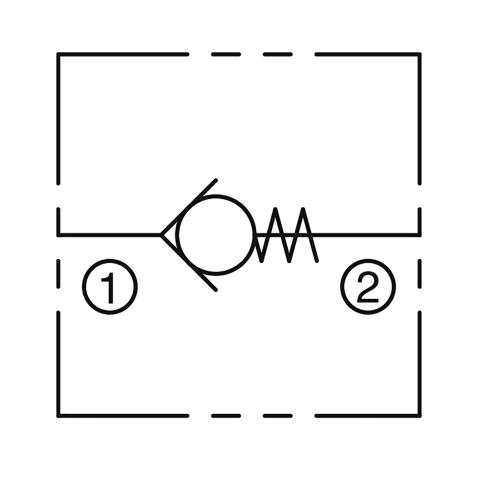

Check valves operate on slight differential pressure. Free flow is permitted in the direction of the arrow, positive check in the opposite direction.

These tough valves are ideal for general industrial and mobile applications including plastic injection molding machines, packaging equipment, machine tools, car washes, hospital beds, and many types of automotive equipment.

Features and Benefits

- Elastomer-free (no O-rings)

- Leak-Tight Ball Check for various medias (except 1")

- Leak-Tight Poppet Check (1")

Specifications

Max Operating Pressure (psi)

5000

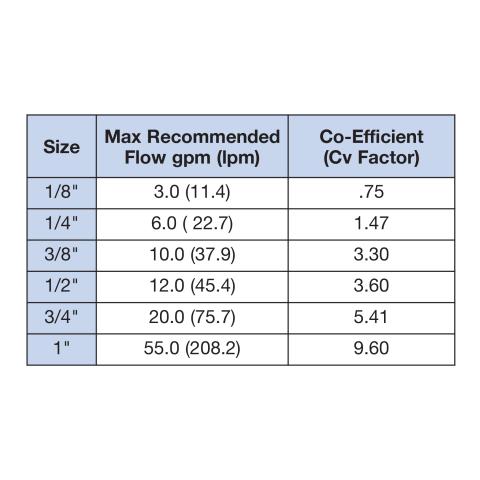

Max Flow gpm

6.00

Max Flow lpm

22.70

Max Cracking Pressure psi

2.50

Cv Factor

1.47

Port Size

1/4"

Port Type

BSPP

Material

Steel

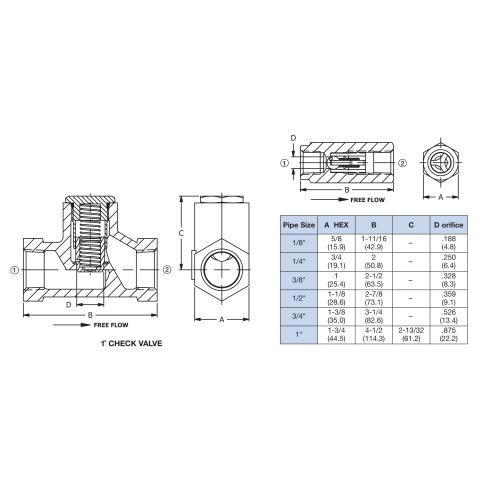

- Maximum Operating Pressure (non-Shock Service)

- Brass: 2,000 psi (138 bar)

- Carbon Steel: 5,000 psi (345 bar)

- Stainless Steel: 5,000 psi (345 bar)

- Ductile Iron: 5,000 psi (345 bar)

- Cracking Pressure (except 1")

- 1 to 2.5 psi (.07 to .17 bar)

- Cracking Pressure (1")

- 3 to 5 psi (.21 to .34 bar)

- Operating Temperature range

- 1/8" – 3/4" -30° to +200° F (-34° to +93° C)

- 1" -15° to +400° F (-26° to +204° C)

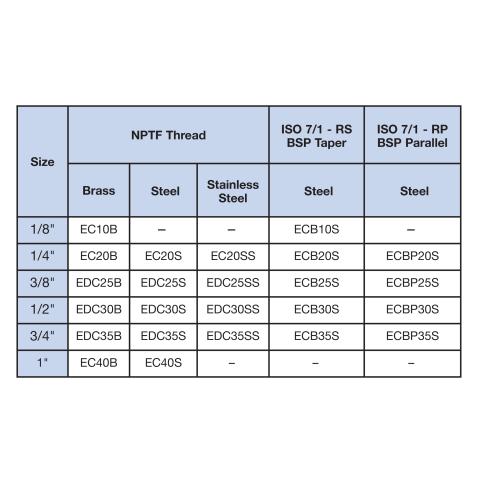

- Threads

- NPTF, BSPT, BSPP

- Materials (except 1")

- Body: Brass, Steel, Stainless Steel 303

- Ball: Stainless Steel 440

- Spring: Stainless Steel 302

- Ball Guide: Delrin®

- Materials (1")

- Body: Leaded Tin Bronze, Ductile Iron

- Plug: Brass

- O-Ring: Viton

- Spring: Stainless Steel 302

- Poppet: Stainless Steel 303