Download Spec Sheet518.3 KB

Download 3D PDF852.75 KB

Download STP29.44 KB

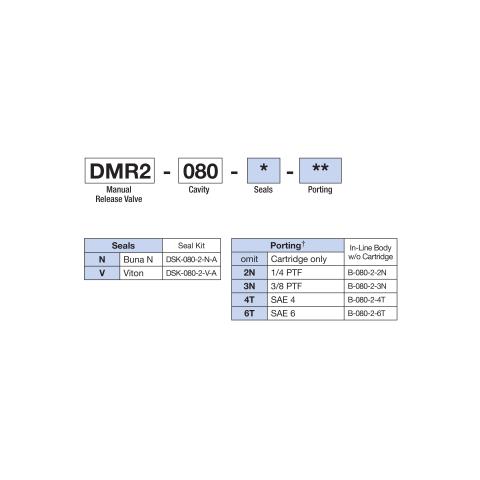

Description

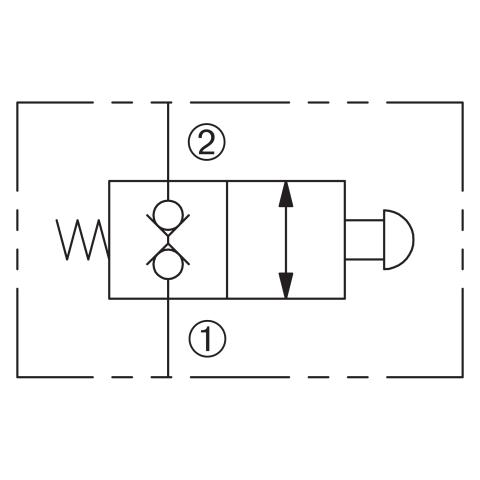

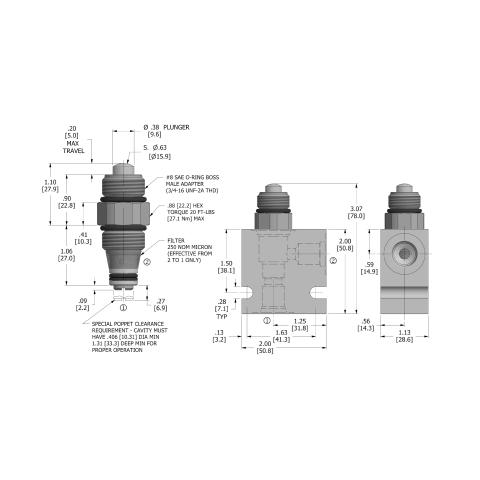

A mechanically-operated cartridge valve designed with positive shut off to be used in load-holding applications.

Operation

The DMR2-080 blocks flow in both directions. When the plunger is actuated, the poppet opens, allowing flow in either direction.

The force required to depress the plunger is the summation of:

- Pressure psi at ➀ x .066

- Pressure psi at ➁ x .011

- 8-lb. spring constant

Note:

- Omit pressure at ➀ if no pressure exists.

- Omit pressure at ➁ if no pressure exists.

Features and Benefits

- Hardened poppet and seat for long life.

- Zero leak.

- Externally threaded for connecting a manual operator.

- Filter screen standard.

- Industry common cavity.

Specifications

Max Operating Pressure (psi)

3000

Flow gpm

5.0

Flow lpm

18.9

Cavity

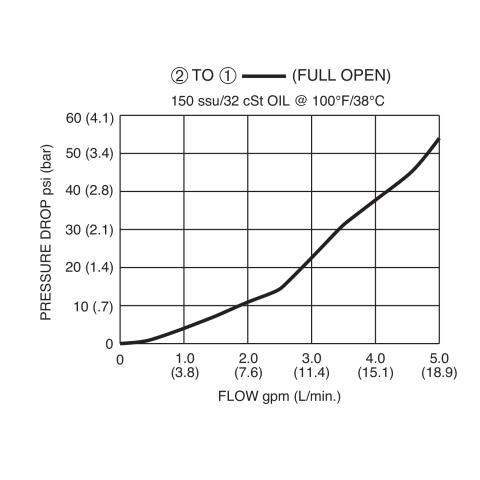

- Operating Pressure: 3000 PSI (207 Bar)

- Flow:

- See PRESSURE DROP VS. FLOW graph.

- Nominal Flow: 5 GPM (18.9 L/min).

- Internal Leakage: 0 drops/min. max. at 3000 PSI (207 Bar)

- Temperature: -30°F to +250°F (-35°C to +120°C)

- Actuation Force: Force (lbs.) = (P① x .066) + (P② x .011) + 8

- Recommended Filtration:

- Critical Application – ISO 17/15/13

- Non-Critical Application – ISO 20/18/14

- Fluids: Mineral-based fluids. For other fluid compatibility, consult factory.

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 PSI (207 Bar).