Download Spec Sheet394.38 KB

Download 3D PDF667.25 KB

Download STP192.39 KB

Description

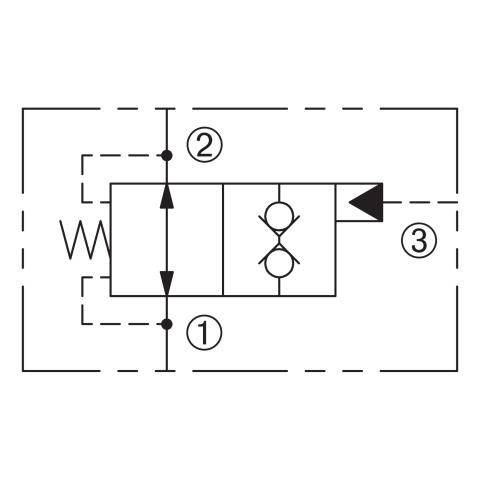

A cartridge valve designed to allow free flow in both directions. The valve can be piloted to block flow in both directions. This valve can used as a load holding or blocking valve.

Operation

Pressure at ➀ or ➁ overcomes the spring-bias poppet and allows free flow between ➁ and ➀ or ➀ to ➁. When required the pilot pressure is achieved at ➂, the poppet is held closed to block flow between ➁ and ➀ and ➀ and ➁. The pilot area ratio port ➂ to ➀ is 2:1 and the area ratio port ➂ to ➁ is 2.8:1.

Features and Benefits

- Hardened poppet and sleeve for long life and low leakage.

- Industry common cavity.

Specifications

Max Operating Pressure (psi)

3000

Flow gpm

10.0

Flow lpm

38.9

Cavity

Valve Style

Poppet

- Operating Pressure: 3000 PSI (207 Bar)

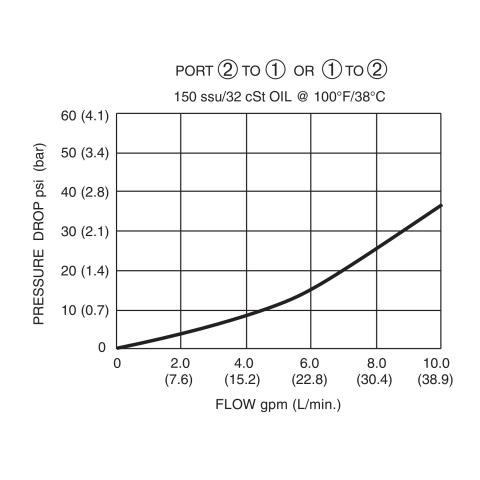

- Flow:

- See PRESSURE DROP VS. FLOW graph.

- Nominal flow 8 GPM (30.4 L/min.)

- Internal Leakage: 5 drops/min. max. at 3000 PSI (207 Bar)

- Crack Pressure:

- 65 PSI (45 Bar) at port ① (biased spring).

- 85 PSI (58.6 Bar) at port ② (biased spring).

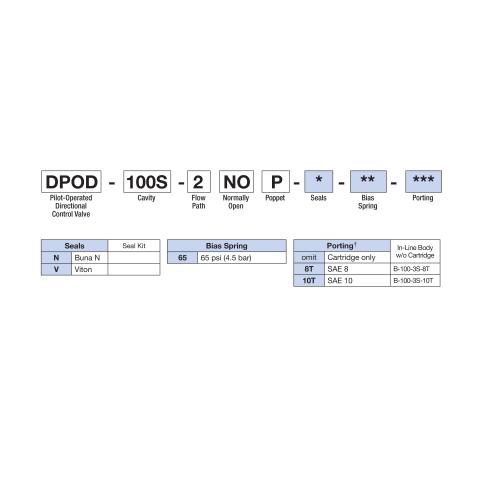

- Bias Spring: 65 PSI (4.5 Bar)

- Pilot Ratio: ③ to ① is 2:1 and ③ to ② is 2.8:1.

- Temperature: -30°F to +250°F (-35°C to +120°C)

- Recommended Filtration: ISO 17/15/13

- Fluids: Mineral-based fluids. For other fluid compatibility, consult factory.

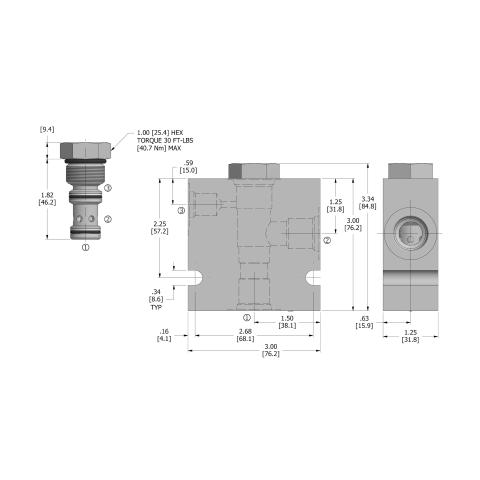

- Cavity/Cavity Tool: 100-3S

- In-Line Body Material: Anodized 6061T6 aluminum alloy rated at 3000 PSI (207 Bar).